GlaswaschmaschineKlöpper

2600 mm R-L

Glaswaschmaschine

Klöpper

2600 mm R-L

Baujahr

2021

Zustand

Gebraucht

Standort

Lleida

Bilder zeigen

Karte zeigen

Daten zur Maschine

- Maschinenbezeichnung:

- Glaswaschmaschine

- Hersteller:

- Klöpper

- Modell:

- 2600 mm R-L

- Baujahr:

- 2021

- Zustand:

- neuwertig (gebraucht)

- Funktionsfähigkeit:

- voll funktionsfähig

Preis & Standort

- Standort:

- Lleida, Spain

Anrufen

Details zum Angebot

- Inserat-ID:

- A16330962

- Referenznummer:

- S-WSH-504

- Aktualisierung:

- zuletzt am 02.02.2026

Beschreibung

Vertical infeed transport

- Vertical 2600 mm washing machine with drying

Optional:

- Tilting table (behind the washing machine)

- Horizontal outfeed transport

- tilting table (discharge)

Vertikaler Einlauftransport

- Vertikale 2600 Waschmaschine mit Trocknung

- Kipptisch (hinter der Waschmaschine)

- Horizontaler Auslauftransport

- Kipptisch (Auslauf)

Description of Line Components

Pos. 1 Loading station, 250kg

With the help of the suction frame, the sheets are taken off the glass rack and they are placed vertically on the tilting table in front of the washing machine. Differences in inclination can be compensated by tilting of the suction frame. The suction frame has a rotating function to collect short formats in upright position and to place them down on the long edge.

Light crane

Trolley crane with a lift system travelling on rails by hand, which are standing on steel supports.

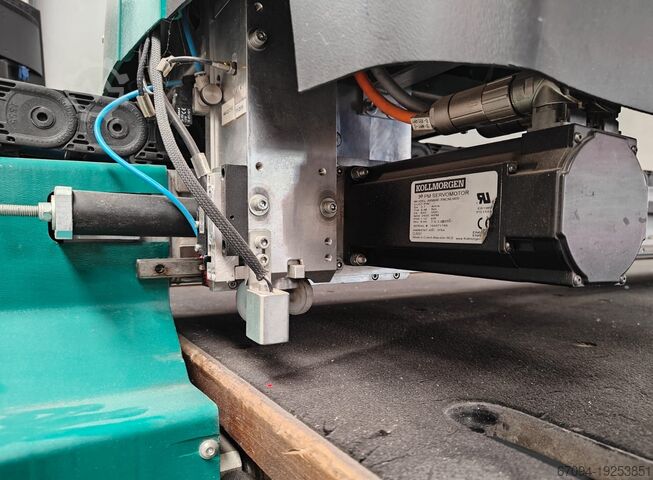

Pos. 2 Vertical Inlet Transport WM

The vertical transport serves as inlet transport in front of the washing machine.

In horizontal position, the glass sheets are placed on Vulkollan transport rollers.

In vertical position transport rollers with Perbunan rings are driven via screw wheels. The transport rollers are arranged in drag bearings placed on a solid welded frame.

Small glass sheets are placed manually on the transport frame. After placing the glass sheet, the transport is activated by push button.

Pos. 3 Vertical Washing Machine with Drying

The washing machine body, washing chambers, recirculation vats and the drying nozzles are made entirely of stainless steel.

The rubber rings of the transport rollers are resistant to cutting oil.

Flat jet spraying nozzles in the pre-rinsing section are fed with city water. Coarse dirt particles removed are directly led into the drain. This reduces contamination of the DI-water circuit for the washing machine.

The washing machine is equipped with energy and water saving cascade system.

Pre-rinsing section with

Flat jet spraying nozzles

Washing section with

3 pairs of brushes,

3 vats and

3 pumps

Acid section with

1 pair of brushes,

1 vat and

1 pump

Drying section with

2 pairs of drying nozzles provide dry edges.

Bwedpfstwphwex Af Heh

Pos. 4 Vertical Inspection Transport with glass Activation Section

The transport serves as Activation Section for the glass surface and as Inspection and Storage Transport before the Tilting Table.

Drive by a geared motor, A.C., frequency-controlled. All the rollers are arranged in drag bearings with a single drive operating pairs of spiral-toothed gear wheels.

The transport rollers are vulcanised and ground.

Pos. 5 Tilting Table with Horizontal Transport and Vertical Inspection

Transport rollers, which are individually driven by worm gear wheels are placed on a solid welded frame. The transport rollers are arranged in drag bearings.

Tilting arms are in horizontal position. The integrated tilting table is made of several profile arms which can be tilted (electro-mechanical by crank mechanism) from the horizontal position by 84°. The tilting speed has its lowest speed at the beginning and at the end of the movement. The glass is tilted from vertical to the horizontal position. If no glass happens to be in the Pre-Heating oven the glass runs into the oven.

- Vertical 2600 mm washing machine with drying

Optional:

- Tilting table (behind the washing machine)

- Horizontal outfeed transport

- tilting table (discharge)

Vertikaler Einlauftransport

- Vertikale 2600 Waschmaschine mit Trocknung

- Kipptisch (hinter der Waschmaschine)

- Horizontaler Auslauftransport

- Kipptisch (Auslauf)

Description of Line Components

Pos. 1 Loading station, 250kg

With the help of the suction frame, the sheets are taken off the glass rack and they are placed vertically on the tilting table in front of the washing machine. Differences in inclination can be compensated by tilting of the suction frame. The suction frame has a rotating function to collect short formats in upright position and to place them down on the long edge.

Light crane

Trolley crane with a lift system travelling on rails by hand, which are standing on steel supports.

Pos. 2 Vertical Inlet Transport WM

The vertical transport serves as inlet transport in front of the washing machine.

In horizontal position, the glass sheets are placed on Vulkollan transport rollers.

In vertical position transport rollers with Perbunan rings are driven via screw wheels. The transport rollers are arranged in drag bearings placed on a solid welded frame.

Small glass sheets are placed manually on the transport frame. After placing the glass sheet, the transport is activated by push button.

Pos. 3 Vertical Washing Machine with Drying

The washing machine body, washing chambers, recirculation vats and the drying nozzles are made entirely of stainless steel.

The rubber rings of the transport rollers are resistant to cutting oil.

Flat jet spraying nozzles in the pre-rinsing section are fed with city water. Coarse dirt particles removed are directly led into the drain. This reduces contamination of the DI-water circuit for the washing machine.

The washing machine is equipped with energy and water saving cascade system.

Pre-rinsing section with

Flat jet spraying nozzles

Washing section with

3 pairs of brushes,

3 vats and

3 pumps

Acid section with

1 pair of brushes,

1 vat and

1 pump

Drying section with

2 pairs of drying nozzles provide dry edges.

Bwedpfstwphwex Af Heh

Pos. 4 Vertical Inspection Transport with glass Activation Section

The transport serves as Activation Section for the glass surface and as Inspection and Storage Transport before the Tilting Table.

Drive by a geared motor, A.C., frequency-controlled. All the rollers are arranged in drag bearings with a single drive operating pairs of spiral-toothed gear wheels.

The transport rollers are vulcanised and ground.

Pos. 5 Tilting Table with Horizontal Transport and Vertical Inspection

Transport rollers, which are individually driven by worm gear wheels are placed on a solid welded frame. The transport rollers are arranged in drag bearings.

Tilting arms are in horizontal position. The integrated tilting table is made of several profile arms which can be tilted (electro-mechanical by crank mechanism) from the horizontal position by 84°. The tilting speed has its lowest speed at the beginning and at the end of the movement. The glass is tilted from vertical to the horizontal position. If no glass happens to be in the Pre-Heating oven the glass runs into the oven.

Anbieter

Hinweis: Kostenlos registrieren oder einloggen, um alle Informationen abzurufen.

Registriert seit: 2019

Anfrage senden

Telefon & Fax

+32 89 53... anzeigen

Diese Inserate könnten Sie auch interessieren.

Kleinanzeige

Brendola

Brendola

288 km

Lkw mit Festaufbau

Iveco

Iveco

Kleinanzeige

Gondelsheim

Gondelsheim

252 km

Brückenkran Hallenkran Kranbahn Kran

Stahl 250KG Hängekran 1,5-6,35 mKranhimmel Portalkran Kran mehrere vorh.

Stahl 250KG Hängekran 1,5-6,35 mKranhimmel Portalkran Kran mehrere vorh.

Kleinanzeige

Velen

Velen

571 km

Kaltkreissäge

BERG & SCHMIDRecord 315/350 S

BERG & SCHMIDRecord 315/350 S

Kleinanzeige

Barbing

Barbing

385 km

Glasbohrmaschine doppelseitig

Schiatti AngeloFPD60

Schiatti AngeloFPD60

Kleinanzeige

Zielona Góra

Zielona Góra

780 km

Tischlermaschine

BOOSTONER-02

BOOSTONER-02

Kleinanzeige

Maasmechelen

Maasmechelen

500 km

Glasschneidetisch

Bottero353BKM-J

Bottero353BKM-J

Kleinanzeige

Barakfakih

Barakfakih

1’843 km

Eckenreinigungsmaschine

PLASTMAK PVC ALÜMİNYUM İŞLEME MAKİNELERİSÇ 6000

PLASTMAK PVC ALÜMİNYUM İŞLEME MAKİNELERİSÇ 6000

Kleinanzeige

Zamość

Zamość

1’180 km

Kopierfräsmaschine

RotoxZOR 941

RotoxZOR 941

Kleinanzeige

Matelica (MC)

Matelica (MC)

544 km

LASERSCHNEIDMASCHINEN - FASERLASERSCHNEIDEN

PRIMA POWERPLATINO FIBER 1530

PRIMA POWERPLATINO FIBER 1530

Kleinanzeige

Scerne

Scerne

653 km

Emmegi Bearbeitungszentrum

EmmegiPhantomatic T4 A

EmmegiPhantomatic T4 A

Ihr Inserat wurde erfolgreich gelöscht

Ein Fehler ist aufgetreten